BWT ALPINE F1® TEAM 2025 SEASON LAUNCH

Unsere Fahrer

Das Bwt Alpine Formel 1 Team Wird Für Die Fia Formel 1 Weltmeisterschaft 2025 Von Einem Dynamischen Fahrer Line-up Geführt: Pierre Gasly Und Jack Doohan.

Pierre Gasly #10

Jack Doohan #61

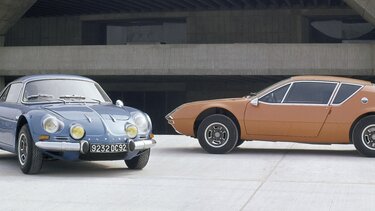

Von der Rennstrecke auf die Straße

Entdecken Sie auch

BWT ALPINE F1® TEAM